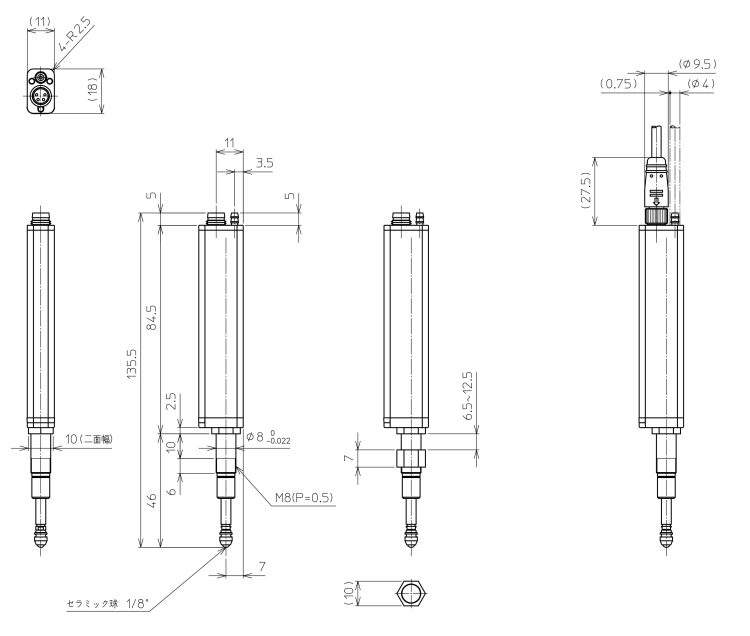

SA-S110/SA-S510

The advanced air-purge technology provides the ultimate,

excellent anti-environmental performance.

This air-purge system dramatically increases the resistance to environment by supplying air to the sensor body to raise the inner pressure and preventing foreign objects from invading from outside. It exhibits strong performance in severe environments where liquids such as permeable oil, coolant liquids and cutting fluids spill over the detector.

Applications

Automatic inspection line in manufacturing processes including

- Grinding parts

- Polishing

- Cutting

- Assembling

We recommend this product to the following industries

- Automotive parts

- Bearings

- Electronic components

specification

| Model | SA-S110AP | SA-S510AP |

|---|---|---|

| Position detection method | Optical absolute linear encoder metho | |

| Measuring range | 10mm | |

| Used fluid | Air | |

| Operating pressure range | 0.05~0.10MPa | |

| Air tube specification | φ4mm /内径φ2.5mm | |

| Air tube specification | Outer diameter: 4 mm Inner diameter: 2.5 mm |

|

| Withstanding pressure | 1.5~3N※2 | |

| Resolution | 0.1μm | 0.5μm |

| Indication accuracy (P-P) ※1 | 1.0μm 以下 | 2.0μm 以下 |

| Mass | Approx. 80 g | |

| ngress protection rating※3 | Equivalent to IP67 | |

| Operating temperature/humidity range | -10~55℃/ 35~80%RH(with no condensation or icing) | |

| Storage temperature/humidity range | -20~60℃/ 35~80%RH/td> | |

| Grounding method | Capacitor grounding | |

| Cable※4 | Sold separately as an option | |

| Measuring probe | Ceramic sphere with a diameter of 3.175 mm | |

※1 The value in the specifications is with an ambient temperature of 20°C.

※2 This value varies depending on the supplied air pressure.It also depends on the assembling accuracy of the product and wear of the sealing material (O-ring).

※3 This applies only when the air tube is connected and the sealing part is not degraded or damaged.

※4 An angle-type connector cable cannot be used.

◎ This type is not fitted with rubber bellows.