- Please contact the following phone number if you have any question forAluminaruby

- Miyota Works +81-267-31-1133 Open hours: 8:30-17:30 (Except weekends and holidays)

- If you have any problems for Aluminaruby to solve, please feel free to contact to us.

- By inquiry form

Aluminaruby have been the backbone behind the watch industry for almost 60 years after receiving technical guidance by Swiss companies.

We strive to continue working to improve customer satisfaction even more.

Many years of experience of aluminaruby manufacturing

Lower price when compared to single-piece crystals.

Multi-kind large quantity production

We provide stable and high quality aluminaruby around the world with our knowhow of miniature parts manufacturing and detailed process control that

we have built up over the years as a watch maker.

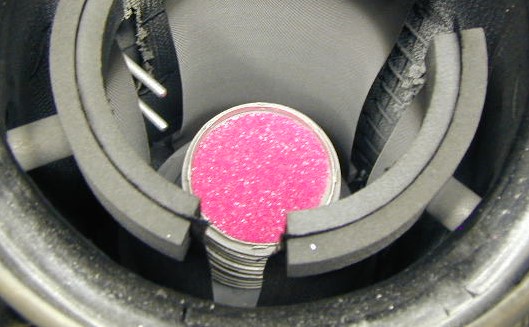

We have developed an ultra-precise processing core technology and we run integrated production from raw material composition, granulating, molding, burning complete through processing.

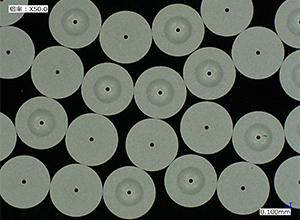

Besides granulation technology and near net molding, we use shape powder molding, extrusion molding or CIP molding technology. In addition precision process finishing, we manufacture aluminaruby and hole aluminaruby with an accuracy of

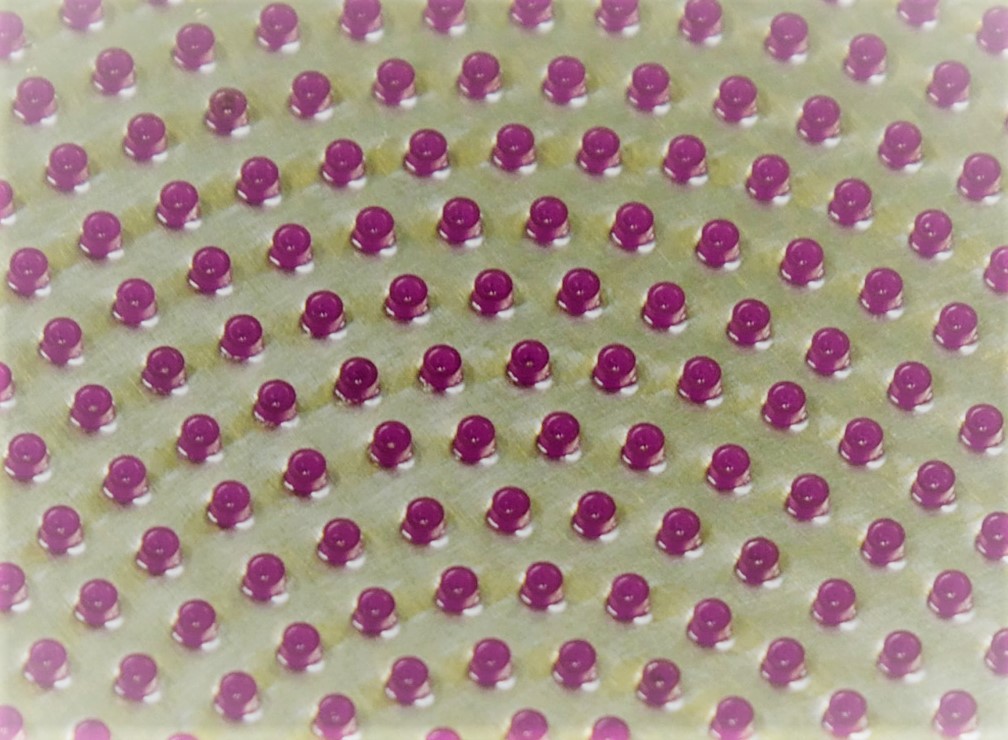

sub-micron dimensions which are not available elsewhere in the market. We use ruby color Almina material and continue producing and developing aluminaruby and hole aluminaruby as close to single crystal quality as possible.

With Near net shapes molding technology, we can mold close to the shape of the completed product. We start cutting from the single crystals and we can reduce the drilling process time significantly.

As one of the few aluminaruby manufacturers, CITIZEN FINEDEVICE contributes to customers by eliminating manufacturing process waste and providing low cost products, we can minimize the burdensome cost for customers as much as possible. With Near net shapes molding technology, we can reduce the machining process, and our technology allows us to manufacture small products with high precision.

Our aluminaruby for watches, measuring devices, analog meters, etc...

can meet the demand with Multi-kind large quantity production.

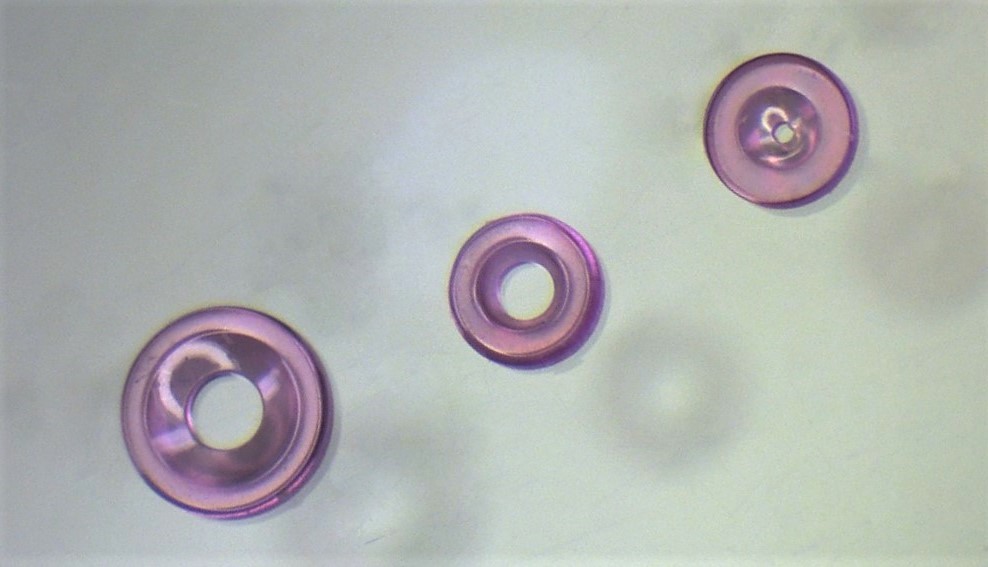

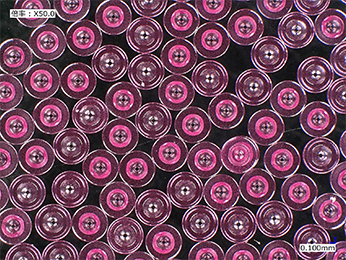

CITIZEN FINEDEVICE uses our mold design knowhow that we built over years, and we are available to propose a variety of designs to meet customer needs. We run integrated production from crushing, granulation, molding, firing, machining, cleaning, oil repellent process complete through inspection, and we can design the ideal design for manufacturing process according to the shape of the product. Available hole inner diameters are Φ0.06-1.18mm, outer diameters are Φ0.5~2mm, and thickness can be ranged between 0.2-0.8mm.

We support the dimensions in addition to dish shape according to customer requests. We can process more complicated shapes such as cylinder or olive. Our production capacity is among the highest in the world, and we meet the demands of up to hundreds of millions products per a year.

CITIZEN FINEDEVICE can manufacture aluminaruby according to the different usages. Please contact us.

- Please contact the following phone number if you have any question forAluminaruby

- Miyota Works +81-267-31-1133 Open hours: 8:30-17:30 (Except weekends and holidays)

- If you have any problems for Aluminaruby to solve, please feel free to contact to us.

- By inquiry form

Technological characteristics of aluminaruby manufacturing

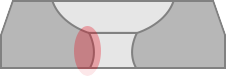

This curvature is the olive

In order to improve inner diameter accuracy, which is the key for bearings, we manufacture wire used for super-precision processing with our original wire manufacturing technology. Particularly, in the processing of split sleeves for optical communications with strict dimensional accuracy requirements, we meet the customer requirements by controlling the accuracy of the processing wire to within 1 μm, and using dedicated in-house manufacturing machines.

Aluminaruby Case Study

Company name: Confidential Industry:Watch industry, measuring instrument industry, analog meter, etc…

Problem for Aluminaruby

The customer built a system to increase the production; however, the vendors were in a difficult situation to increase the production due to the problems of production capacity and control systems; therefore, the customer was looking for a second vendor. The customer checked manufactures all over the world via the internet, but could not find a reliable company. Eventually, the customer happened to find our company and made the judgment that all the necessary conditions were met. Subsequently, the customer contacted us.

Rough estimation – Site visit to our company and marketing

The customer sent detailed specifications and drawings via e-mail, and we were asked if we are capable of performing this project and also asked to present a rough estimation. We called each member in charge and decided to accept the project and presented a rough estimation after multiple discussions regarding mass production. Since the customer was in rush enter mass production, the customer immediately visited our site and became satisfied by checking the actual state of our quality control system and technological capabilities. Later, we asked the customer to talk about the detailed business story, and we also listened to the customers enough. Both sides agreed with the business plan, made a schedule for industrialization and started making the prototype.

Production - Delivery process

To meet the strict requirements, we gathered detailed data and made improvements at the same time to each manufacturing process, and submitted test samples multiple times. We also discussed problems with the customer each week and solved any problems. We were able to attain approval from not only the customer, but also from the certification authority.

Pricing and Delivery date

When we decided the final mass production volume, we proposed the official estimation and cost roadmap. The initial price for the mass production was a slightly expensive compare to the 1st vendor’s estimate; however, we were able to show the roadmap along with the price, and we could reach agreement. We could also delivered the product by the specific delivery date.

Customer feedback

The customer acknowledged our capability of quality and technique and promised to first come to us when making new product inquiries in the future. We continue to gain 100% score in “Vendor assessment” based on initial delivery. CITIZEN FINEDEVICE is recognized as the top vendor for satisfaction and credit improvement.

We are capable of dealing with the industries that require high quality and high precision.

- Please contact the following phone number if you have any question forAluminaruby

- Miyota Works +81-267-31-1133 Open hours: 8:30-17:30 (Except weekends and holidays)

- If you have any problems for Aluminaruby to solve, please feel free to contact to us.

- By inquiry form

FAQ about Aluminaruby

Can I purchase all aluminaruby which are necessary for watches?

Please feel free to ask us according to your needs.

Which color can you produce?

Red, white, black, grey, blue, etc… (Translucency is adjustable for red and white)

Characteristics comparison for ceramics (hardness, wear resistance, etc…)

| Material name | Sialon | Zilconia | Alumina | Silicon nitride |

High-carbon chrome bearing steel (SUJ2) |

| Specific gravity | 3.2 | 6.0 | 3.9 | 3.2 | 7.8 |

| Vickers hardness value (Hv) | 1600 | 1300 | 1700 | 1500 | 700 |

| Vickers hardness value (Hv) | 6.0 | 5.8 | 3.0 | 6.0 | 15 |

| Thermal expansion coefficient | 3 | 10 | 8 | 3 | 10 |

What kind of materials can you use for the products?

Alumina , Zilconia , Sialon

What is the best dimension accuracy?

Hole dimension accuracy up to 6 μm is available as standard.

Please ask for further information.

CITIZEN FINEDEVICE can manufacture aluminaruby according to the usage. Please feel free to ask us.

- Please contact the following phone number if you have any question forAluminaruby

- Miyota Works +81-267-31-1133 Open hours: 8:30-17:30 (Except weekends and holidays)

- If you have any problems for Aluminaruby to solve, please feel free to contact to us.

- By inquiry form