- Please contact the following phone number if you have any question forMagnets

- Miyota Works +81-267-31-1133 Open hours: 8:30-17:30 (Except weekends and holidays)

- If you have any problems for Magnets to solve, please feel free to contact to us.

- By inquiry form

We have accumulated quality and technologies over the years and gained sufficient knowledge to control the magnet characteristics.

Our deep knowledge and integrated production capability allow us

to provide detailed advice to our customers.

Deep knowledge and experiences for magnet characteristics.

Top rated low cost in the industry.

Capabilities for a variety of usages.

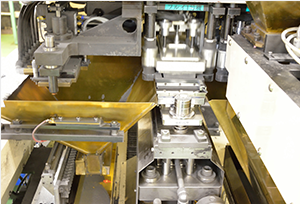

Technology and skill for crushing materials, press molding, sintering, processing, and testing have been built up over the years that enable us to meet customer requests.

Please feel free to let us take care of any difficulties which other companies are not capable, such as “too small to work for”, samarium-cobalt magnet, or bonded neodymium magnets which are complicated to handle.

Our years of experience as a clock manufacture allows to produce small high precision cylinder magnets of φ2mm or less. Besides granulation technology and near net shape, we use press powder molding, extrusion molding or CIP molding technology. In addition to precision process finishing, we also manufacture magnets with micron accuracy which are not available in the market. We use magnetic field molding machines and manufacture anisotropic sintered magnets. Sintering after molding is performed under the best conditions for the material characteristics, not only controlled temperature, but also air, vacuum and inert gas atmosphere, etc…and we make sure that we manufacture products with minimum defects. Our products have characteristics, such as corrosion and heat resistance, which enable them to be used under the severe environment.

We save labor and eliminate waste of process on daily basis, and always think

about how to improve customer satisfaction.

Near net shapes (molding close to the shape of the completed product) with ultraprecise molding technology, saving a processing allowance in the later processes allows us to be environmental friendly and provide products at lower price than other companies. We also reduce defective products to a minimum by adopting automatic visual inspection device.

Current products in the market are continuously becoming more compact.

We try to contribute to our society by improving compact, high precision, cylinder shape products and expanding applications.

Because of our diverse business operations, we are able to offer proposals from unique perspectives not available from other companies. Our diverse expertise allows us to provide innovative solutions that are not bound by conventional frameworks.

Production of magnets which involve a high level of difficulty is possible with additional negotiation.

- Please contact the following phone number if you have any question forMagnets

- Miyota Works +81-267-31-1133 Open hours: 8:30-17:30 (Except weekends and holidays)

- If you have any problems for Magnets to solve, please feel free to contact to us.

- By inquiry form

Characteristics of Samarium-cobalt sintered magnet

Samarium-cobalt sintered magnet is ideal for using in the environments conducive to rust formation as well as high temperature environments. It is possible to use in a wide variety of industrial products such as vehicle products and actuators.

Magnet characteristics list

| Material | Fired magnet | Bonded magnet | |

| Anisotropy | Isotropic | ||

| Magnetic field direction | Right-angle magnetic field press | ||

| Composition | Sm2Co17 | Nd | |

| Br | (T) | 1.05~1.12 | 0.66~0.71 |

| (KG) | 10.5~11.2 | 6.6~7.1 | |

| Hcj | (KA/m) | 500~1200 | 720~800 |

| (KOe) | 6.2~15.1 | 9.0~10.0 | |

| BHmax | (KJ/m3) | 239~255 | 80~88 |

| (MGOe) | 30.0~32.0 | 10.0~11.0 | |

| Necessary magnetization field | (KA/m) | >1600 | >2000 |

| (KOe) | >20 | >25 | |

| Reversible permeability | 1.0 | 1.2 | |

| Reversible temperature coefficient | (%/°C) | -0.03 | -0.1 |

| Density | (g/cm3) | 8.3 | 5.6 |

| Coefficient of thermal expansion | (/°C) | 8×10-6 | 1.0×10-5 |

Magnets Case Study

Company name: confidential / Industry: Clock industry

Problem for Magnets

The customer had difficulties in lowering magnets purchase price and stabilizing current vendor character. It was also hard to find a vendor which handles Samarium-cobalt sintered magnet since the number of vendors has decreased.

The product or solution

Our engineer presented at the customer meeting and we were able to discover the customer issues. According to the customer, “Defects have been detected due to the volume of the magnet being changed by chipping and cracking, and weaker magnet characteristics were found. It is unknown if the cause is related to the magnet processing or if the defects were missed during visual inspection. Anyhow, defects have been detected from the vendors, and not much improvement have been made so far.” We explained to the customer, “Our company’s processing technology has been praised by customers”. “We check every product with an automatic visual inspection device, and we can reduce minimize defective products.” We also told customer that we can propose different solutions from diverse areas with our accumulated technologies and qualities over years.

Marketing (Hearing) 〜 Process from production to delivery

We could gain trust in discussions, and the customer made a suggestion about the drawing. We handled the prototype production and manufactured the prototype with the short lead time by leveraging existing molds. At the same time, we evaluated the projected sale price and submitted the estimated price of mass production.

Pricing

The customer was satisfied with the price. The initial evaluation was also good, and we gained customer confidence since we could handle the 2nd prototype with a short lead time as well.

Delivery

We delivered the product by the due date that was agreed upon.

Customer feedback

We heard the customer wanted to introduce our products sooner due to the significant cost savings and reduced defect rate.

- Please contact the following phone number if you have any question forMagnets

- Miyota Works +81-267-31-1133 Open hours: 8:30-17:30 (Except weekends and holidays)

- If you have any problems for Magnets to solve, please feel free to contact to us.

- By inquiry form

FAQ about Magnets

How small of products can your company produce?

Central zone ODΦ1.0mm×IDΦ0.3×t0.5mm

minimizing ODΦ0.8mm×IDΦ0.2×t0.2mm Further miniaturization can possible.

What are the characteristics and features of samarium-cobalt magnet?

Due to the high corrosion and heat resistance, samarium-cobalt is able to be used under the severe environments without surface treatment. It becomes stronger with surface treatment which expands usage potential.

Can you perform plate processing for bonded neodymium magnet?

Yes, electroless plating is available.

What kind of benefits does your samarium-cobalt magnet have when compared to competitors’ products?

Our advanced brittle material machining technology that we have built up over the years are superior and we have established superiority in knowledge and experience when compared to the competition.

- Please contact the following phone number if you have any question forMagnets

- Miyota Works +81-267-31-1133 Open hours: 8:30-17:30 (Except weekends and holidays)

- If you have any problems for Magnets to solve, please feel free to contact to us.

- By inquiry form

Characteristics of Samarium-cobalt sintered magnet are that they have high corrosion and heat resistance,

and are possible to use in many occasions.