- Contact

- Inquiry form

Foundry business of CITIZEN FINEDEVICE Co.,LTD.

Using proprietary technologies, the company provides services ranging from design to mass production in terms of products requiring micro machining.

The company provides relevant suggestions on the use of technologies in terms of design in the substrate selection stage, and promotes and develops mass production within the field of vision.

In addition to Si substrates, the company also provides services in relation to crystal, glass and ceramics.

In addition, it also provides services for products in relation to functional film forming such as hydrophilic films and water-repellent films to further enhance their added value.

The company provides services ranging from wafer processing to packaging and services relevant to electrical characteristic inspection.

The company provides high vacuum bonding and packaging services in terms of AuSn solder.

Current achievements of foundry business

The company has produced the following products in the course of current business development.

MEMS fixtures include stencil masks, packaging fixtures, electrical gauging fixtures, alignment trays, suckers and medical micro fixtures.

As for microwell plates, there are MALDI-TOF plates and nucleic acid detection and analysis plates.

Microfluidic includes micro reactors and antibody detection chips.

In terms of precision molds, there are molds for resin micro processing such as PDMS and COP.

Proprietary technologies of CITIZEN FINEDEVICE Co.,LTD.

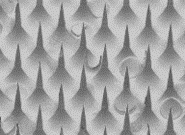

LIGA products

LIGA is a technology consisting of lithography, galvanoformung and abformung.

Through LIGA technology, fine structures with high width-depth ratio (100:1) can be produced and the surface roughness of the side wall can reach Ra = 10nm. It helps reach the optical mirror use level.

This technology is applicable to high value-added products or products requiring super precision molding.

This technology can be used to realize high-precision metal processing. At present, CITIZEN FINEDEVICE Co.,LTD. is using this technology to manufacture high-precision gears.

We also use this technology to provide services ranging from design to production for all kinds of high-precision metal parts.

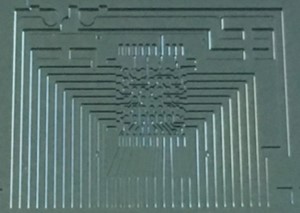

Photolithography

Photolithography is the technology that makes the exposed part and

unexposed part generate characteristic patterns by exposing the

wafer coated with photoresist, a kind of photosensitive material.

Substrate materials include Si, crystal, glass and ceramics.

In addition to photoresist wet films, dry films can also be selected.

Coating methods include film forming, spin coating, electrodeposition and spraying.

Suggestions are provided according to customer requirements.

Dry etching

Dry etching is a kind of etching technology utilizing reactive gas.

Deep RIE realizes high-speed machining and high depth-to-width

ratio (opening 1: depth more than 30) based on Bosch process,

and can help penetrate substrates over 2mm.

For products having requirements in verticality, the accuracy level can reach 90.0 ° ± 0.1 °.

In addition to Si etching, parallel-plate RIE provides etching of oxide films and nitride films.

Ion milling realizes etching of various metal films.

Wet etching

Wet etching is a kind of etching technology utilizing agents with the properties of corroding and dissolving metals.

It includes isotropic etching and anisotropic etching of Si substrate, and crystal and metal etching.

In addition, it also provides fluoric acid treatment.

Micro blasting

This technology is used to process the substrate by spraying abrasive.

Compared with other etching technologies, its processing speed is faster, and any substrate can be micro-machined with it.

In addition, combined with other etching technologies, the R-shaped contour of the edge part can be achieved.

It is most suitable for fine pitch machining of ceramics and glass.

Film forming

From various PVD methods such as sputtering, vacuum deposition, ion plating and thermal oxidation, as well as CVD methods such as TEOS film method, we propose the best scheme for you.

It is possible for the abundant sputtering target materials to realize three-layer overlap in three dimensions simultaneously in the same vacuum.

Metal films, oxide films and polyimide films can be made.

New functions can be added through the combination of thins films.

With hydrophilic, water-repellent and hydrophobic films utilized, the sample control on the cell inspection chips can be realized.

Substrate processing

The company uses a laser perforation machine to conduct perforation processing.

A blade cutting machine is available to carry out wafer cutting.

AuSn bonding, vacuum packaging

The firm bonding of materials that are difficult to be joined such as metal and glass is realized.

In the vacuum packaging process, nitrogen is injected into the vacuum to adjust the vacuum degree, and so the packaging state under appropriate vacuum degree is achieved.

The components completed by using the melting characteristics of AuSn at 280℃ can be packaged by reflow soldering.

In addition, AuSn is also applicable to human contact parts in terms of safety.

Compared with organic cement, AuSn cement has strong drug resistance and does not produce outgas.

Packaging techniques

The company’s main product CM315 series die bonding equipment is used. Its production performance reaches more than 15 million per month.

Wire bonding equipment is used in TCXO production, and the company can provide relevant services.

- Contact

- Inquiry form